ARU Products - Applicator Systems

ARU designs and manufactures professional applicator systems for the automated installation of anti‑condensation and soundproof membranes onto metal roofing panels. These high‑precision machines ensure uniform bonding of the self‑adhesive felt layer directly during panel profiling, eliminating manual application and increasing productivity.

Discover our applicator models below.

Applicator ARU FIX

Applicator ARU MOVABLE

Applicator ARU MOVABLE - Hot-Wire Cutting

Applicator ARU MOVABLE - Servo Motor

Applicator ARU Apply Felt UP

Applicator ARU UP & DOWN

Felt Applicator ARU with Protective Foil Application

ARU Prevent Capillarity – Automatic Operation with Profiling Line

ARU Applicator Felt - Unwinding – Winding Felt Device

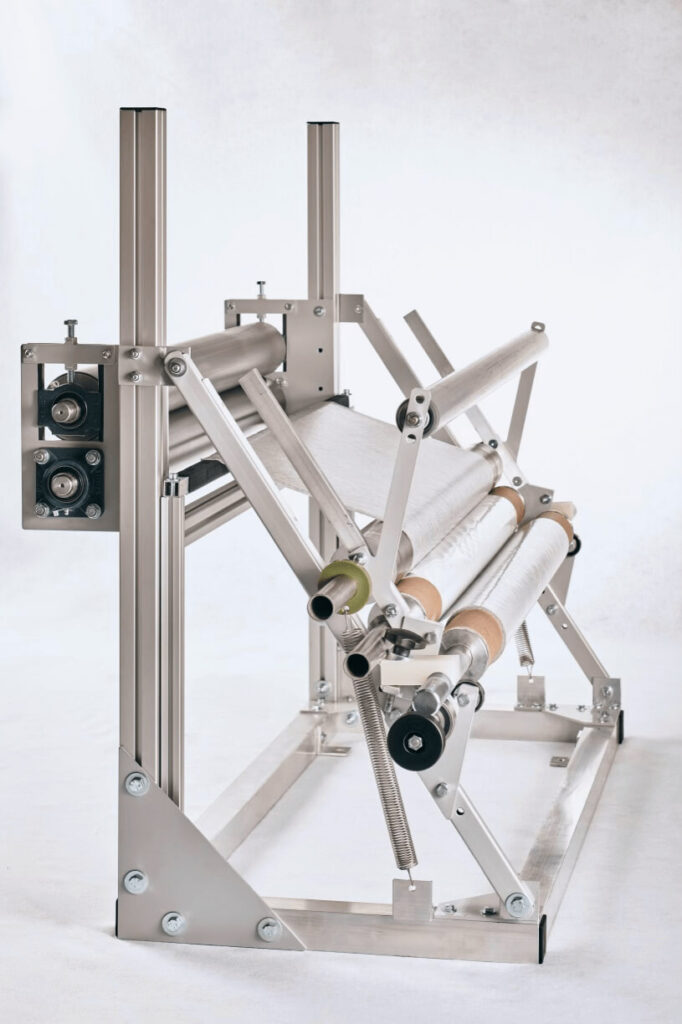

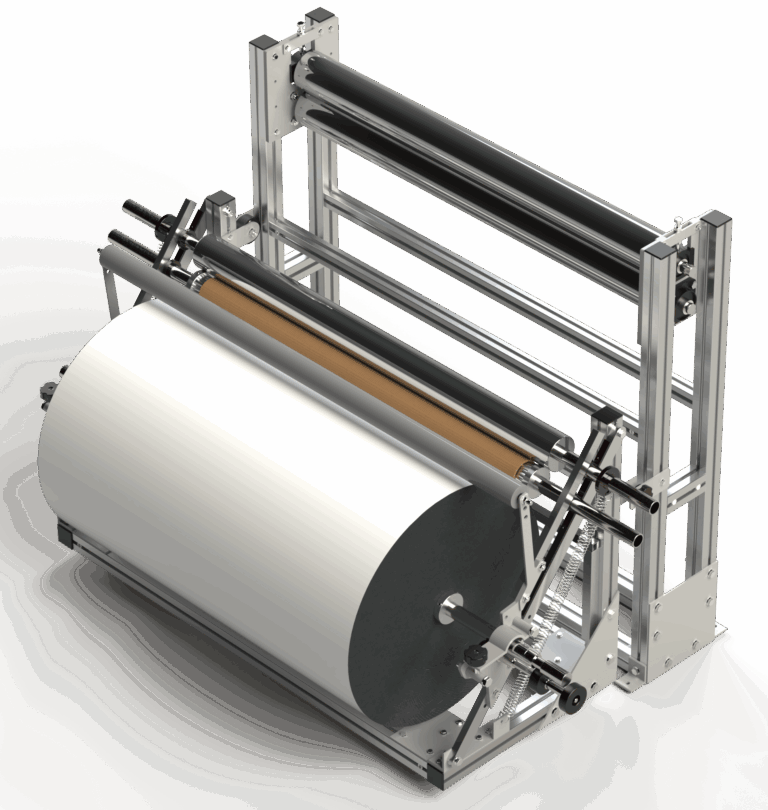

ARU Applicator - Fixed

Overview

The ARU Fix Applicator is a stationary system developed for continuous and repeatable application of felt directly onto metal sheets in profiling lines. Fixed applicator for continuous lamination of anti-condensation fleece onto sheet metal. ALU BOSCH frame, fixed to the floor, for stable, repeatable lamination. Adjustable height alignment of pressure rollers, adjustable brake for felt roll and rubberized pressure rollers ensure controlled feeding and even bonding. Supports rolls up to Ø1000 mm - standard roll is 700 mm. This model is ideal for large‑scale manufacturers that require consistent output quality without repositioning equipment.

Key Features

- Heavy‑duty stationary frame made from ALU BOSCH profiles

- Continuously adjustable brake system for controlled roll tension

- Pressing rollers for reliable adhesion of DRIPSTOP® to sheet metal

- Protective foil winding system (optional) for adding top‑side protection film

- Hot‑wire cutting upgrade for precise felt edge finishing

- Support for DRIPSTOP® rolls up to Ø1000 mm

- Smooth roller‑height adjustment for accurate alignment with profiling line

- Durable INOX pressing rollers for long service life and corrosion resistance

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Frame: fixed ALU BOSCH profile construction

- Mounting: anchored to production floor

- Adjustment: manual height control

- Adjustment: pneumatic height control

- Pressing rollers: INOX steel, adjustable

- Brake system: continuous adjustable tension brake

- Foil application: optional protective foil module

Dimensions

- Width: 2000 mm

- Height: 1300 mm

- Depth: 800 mm

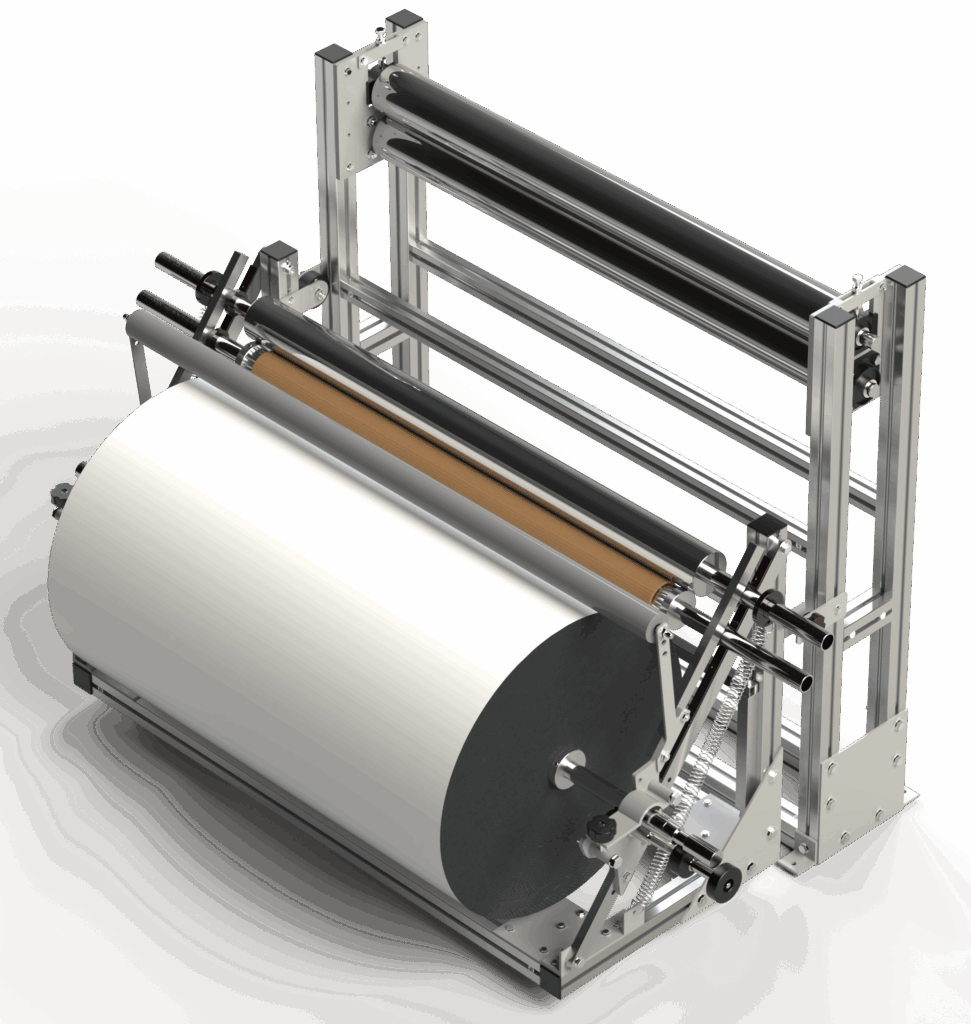

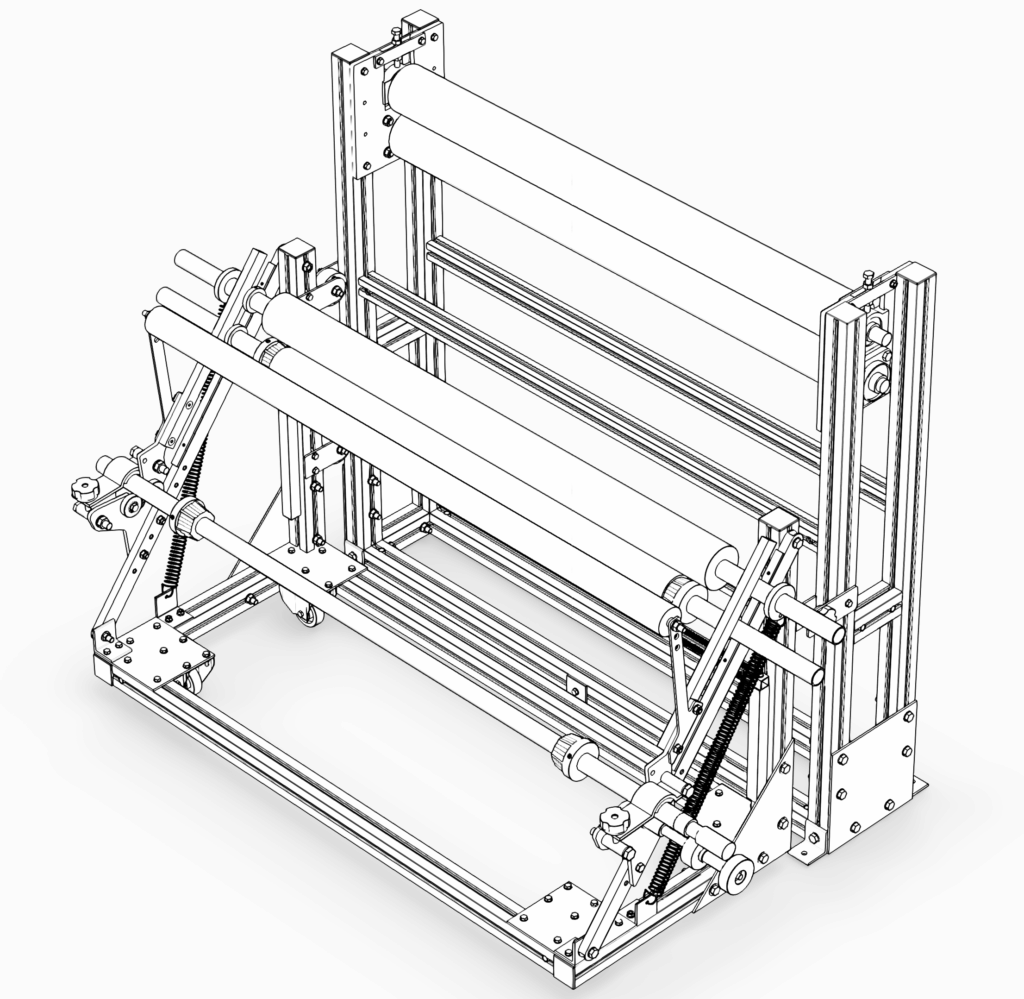

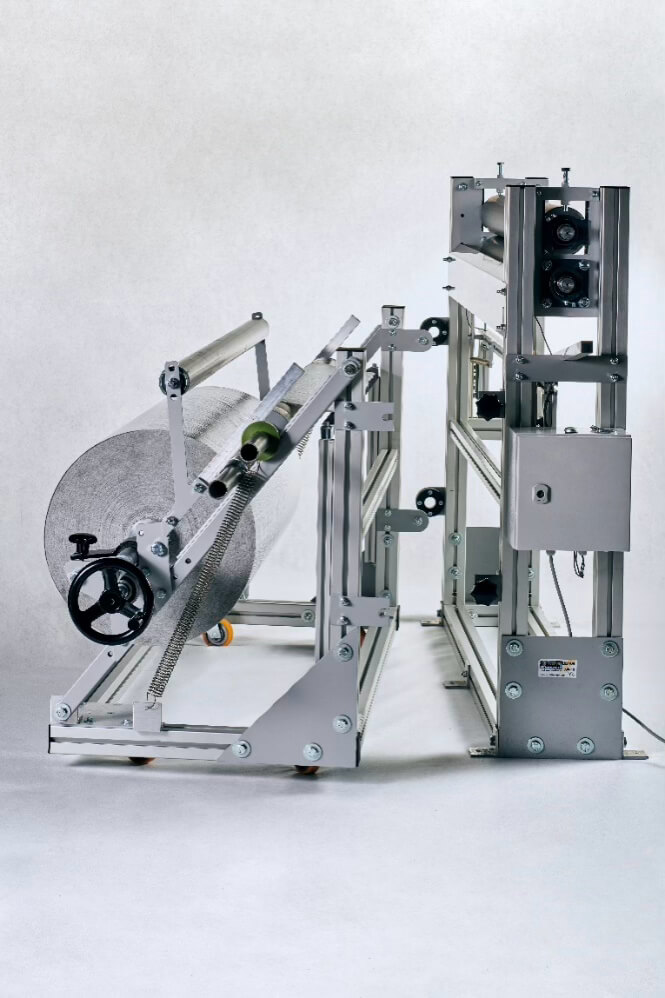

ARU Applicator - Movable

Overview

The ARU mobile applicator is designed for flexible and efficient application of anti-condensation felt to metal roof panels. The applicator is made of ALU BOSCH profiles and consists of original structural elements, allowing for multiple settings depending on the roll diameter and pressure roller height.

Its mobile design on wheels allows operators to easily move the applicator for work on different production lines, quickly and safely replace the felt roll, and prepare for profiling. The fixed part of the applicator consists of pressure rollers on a frame that is fixed to the floor in front of the entrance to the profiling line. The height of the pressure rollers is adjusted to the height of the sheet metal inlet into the profiling line.

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion-resistant

- Quick adjustment and adaptation of roller height and anti-condensation fleece roll diameter

- Mobility on wheels for easy positioning and use on multiple profiling lines

- The pressure roller frame ensures even and uniform lamination

- The standard diameter of the anti-condensation fleece roll is 700 mm, the applicator can be increased to a diameter of 1000 mm

Technical Specifications

- Standard felt roll diameter: 700 mm – can be increased to 1000 mm

- Frame: modular ALU BOSCH construction

- Movement: movable on 4 wheels, 2x fixed – 2x movable

- Pressure rollers covered with silicone-rubber coating

- Frame fixation: 6-point floor mounting system

Dimensions

- Width: 2000 mm

- Height: 1300 mm

- Depth: 1200 mm

ARU Applicator - Movable - Hot‑Wire Cutting

Overview

The fixed and mobile applicator has the option of cutting fleece with a hot wire, which simplifies the sometimes difficult cutting with a knife or scissors.

The cutting system consists of:

- 30V transformer with cabinet

- Electrical cabinet with hot wire intensity control

- Hot wire overheating protection

- Hot wire mounting brackets

- The cutting movement can be manual or pneumatic

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion‑resistant

- Quick setup and adjustment of roller height and DRIPSTOP® roll diameter

- Wheel‑based mobility for easy positioning along multiple profiling lines

- Pressure‑roller frame guarantees consistent and even lamination

- Optional EM 24 V drive with left‑right felt alignment control

- Integration with height sensors allows automated roller adjustments

- Pneumatic cylinders on pressing rollers for optimal pressure and surface contact

- Support for DRIPSTOP® rolls up to Ø1000 mm

- Integrated hot‑wire cutting module for clean, precise trimming of felt edges

- Ideal for variable panel lengths, minimizing off‑cuts and material waste

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Hot‑wire cutting module: integrated unit with PID temperature control and guided edge trimming for clean, precise cuts

- Variable‑length operation: on‑the‑fly length changes with synchronized feed to minimize off‑cuts and material waste

Dimensions

- Width: 2000 mm

- Height: 1300 mm

- Depth: 1200 mm

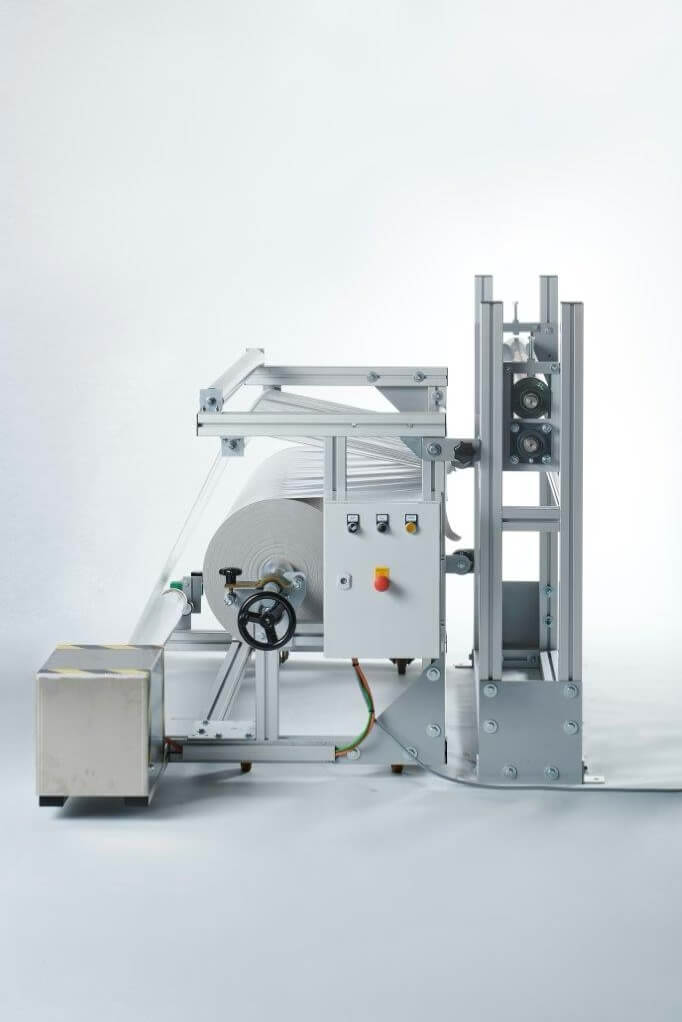

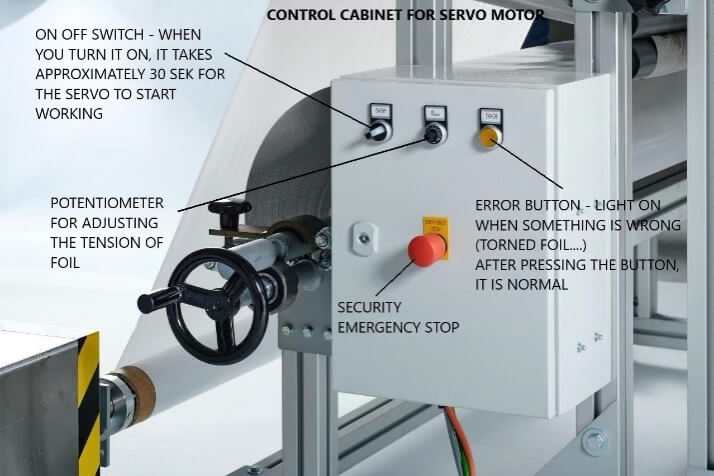

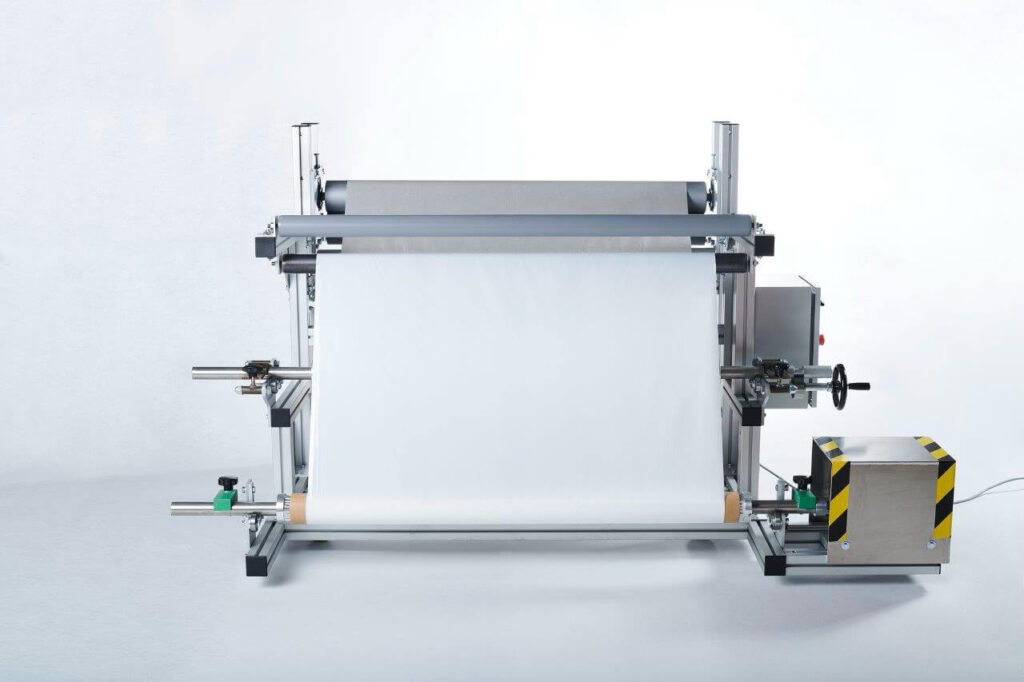

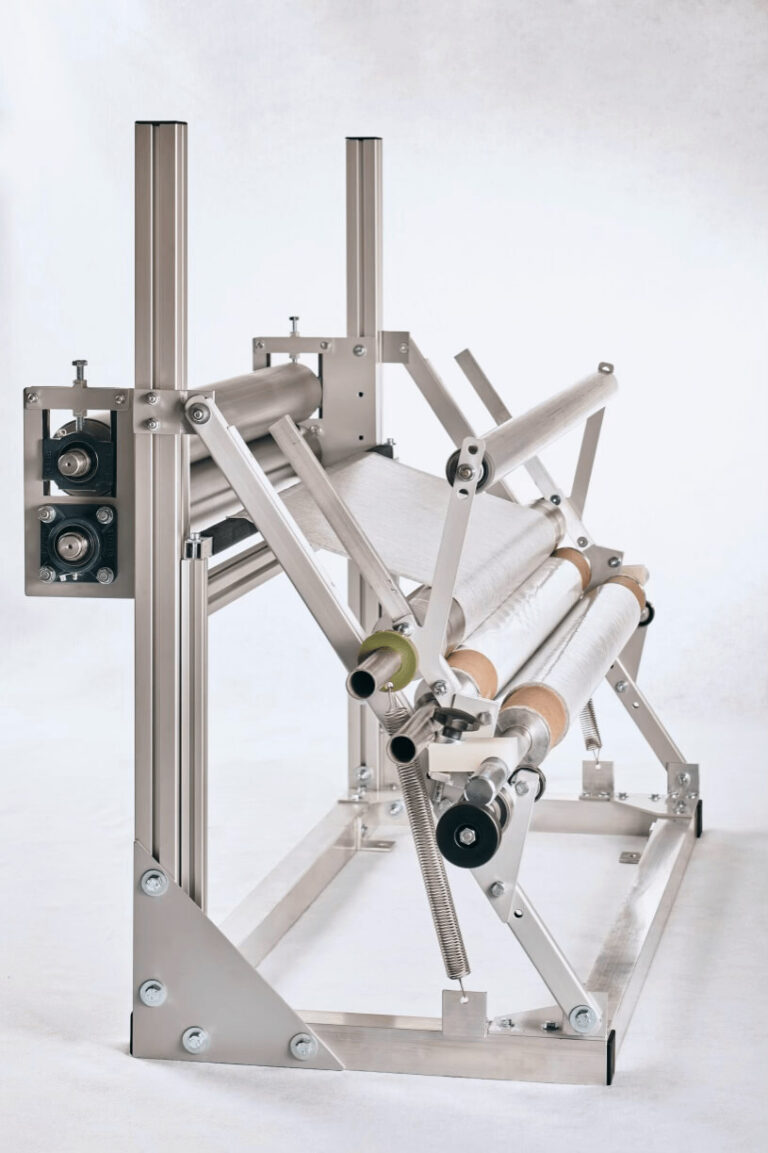

ARU Applicator - Movable - Servo motor

Overview

Winding the foil with a servo motor enables controlled separation of the foil from the fleece. By adjusting the tension of the foil unwinding on the servo motor, we enable higher quality winding. Adjustable foil winding tension enables higher quality winding with different types of anti-condensation fleece. electrical cabinet with servo motor control cabinet with stepless film tension adjustment additional unidirectional rotating rollers for separating the film and fleece. shaft for quick roll of foil replacement

Additional parts of the mobile applicator:

- Electrical cabinet with servo motor

- Control cabinet with stepless film tension adjustment

- Additional unidirectional rotating rollers for separating the film and fleece

- Shaft for quick roll of foil replacement

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion‑resistant

- Quick setup and adjustment of roller height and DRIPSTOP® roll diameter

- Wheel‑based mobility for easy positioning along multiple profiling lines

- Pressure‑roller frame guarantees consistent and even lamination

- Optional EM 24 V drive with left‑right felt alignment control

- Integration with height sensors allows automated roller adjustments

- Pneumatic cylinders on pressing rollers for optimal pressure and surface contact

- Servo‑motor‑controlled foil winding delivers constant tension with synchronized feed

- Engineered for continuous industrial operation; optimized for DRIPSTOP® rolls up to Ø900 mm

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Foil winding: servo‑driven take‑up with closed‑loop web‑tension control (PID) using encoder/dancer feedback; optimized for DRIPSTOP® rolls ≤ Ø900 mm

- Feed synchronization: electronic line‑shaft via encoder for automatic speed matching to profiling line; continuous‑duty servo drive with slip compensation

Dimensions

- Width: 2100 mm

- Height: 1300 mm

- Depth: 1400 mm

ARU Applicator - Apply Felt UP

Overview

The applicator from above enables the application of anti-condensation fleece from above - onto the sheet metal from the top.

There are three options for fixing the applicator:

- Fixing before the entrance to the profiling line

- Fixing above the entrance to the profiling line

- Fixing during the profiling line at a predetermined free location

Additional parts of the applicator for application from above:

- Additional bracket for fixing the applicator above the production line at an agreed height

- Additional rollers for guiding the fleece

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion‑resistant

- Quick setup and adjustment of roller height and DRIPSTOP® roll diameter

- Wheel‑based mobility for easy positioning along multiple profiling lines

- Pressure‑roller frame guarantees consistent and even lamination

- Optional EM 24 V drive with left‑right felt alignment control

- Integration with height sensors allows automated roller adjustments

- Pneumatic cylinders on pressing rollers for optimal pressure and surface contact

- Specialized upward felt application (Apply Felt UP): ensures stable, uniform bonding when applying from below on large panels

- Engineered for continuous industrial operation; optimized for DRIPSTOP® rolls up to 1000 mm

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Felt application: upward (Apply Felt UP); ensures stable, uniform bonding of anti‑condensation felt from below upward on large panels

Dimensions

- Width: 2100 mm or more

- Height: 1800 mm or more

- Depth: 1100 mm

Applicator ARU - UP & DOWN

Overview

The applicator enables application from below and above on a two-level profile line.

The applicator for application from above is fixed at the height of the upper profile line.

The applicator for application from below is movable and is fixed to vertical supports for application from above, and roll fleece can be changed outside the profile line.

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion‑resistant

- Quick setup and adjustment of roller height and DRIPSTOP® roll diameter

- Wheel‑based mobility for easy positioning along multiple profiling lines

- Pressure‑roller frame guarantees consistent and even lamination

- Optional EM 24 V drive with left‑right felt alignment control

- Integration with height sensors allows automated roller adjustments

- Pneumatic cylinders on pressing rollers for optimal pressure and surface contact

- Dual‑direction felt application (UP & DOWN): supports upward and downward bonding for maximum adaptability to panel orientations and roof geometries

- Engineered for continuous industrial operation; optimized for DRIPSTOP® rolls up to 1000 mm

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- UP & DOWN applicator: bi‑directional felt lamination (upward/downward) for multi‑orientation panels; maximizes adaptability to complex roof geometries

Dimensions

- Width: 2100 mm or more

- Height: 1800 mm or more

- Depth: 1100 mm

Fellt Applicator ARU - with Protective Foil Application

Overview

The fixed and mobile applicator can be equipped with an additional unit for applying protective film to the manufactured panel from above.

The applicator is additionally equipped with:

- A pneumatic clamping axle for clamping the foil roll

- 2x left and right clamping heads for the foil roll

- A brake on the clamping head for regulating the tension of the protective film

Key Features and Advantages

- Modular ALU BOSCH frame: robust, lightweight, corrosion‑resistant

- Quick setup and adjustment of roller height and DRIPSTOP® roll diameter

- Wheel‑based mobility for easy positioning along multiple profiling lines

- Pressure‑roller frame guarantees consistent and even lamination

- Optional EM 24 V drive with left‑right felt alignment control

- Integration with height sensors allows automated roller adjustments

- Pneumatic cylinders on pressing rollers for optimal pressure and surface contact

- Combined felt application and protective foil lamination in one continuous pass; delivers a clean, protected surface ready for transport or installation

- Engineered for continuous industrial operation; optimized for DRIPSTOP® rolls up to 1000 mm

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Felt application and protective foil lamination in one continuous operation.

Dimensions

- Width: 2100 mm

- Height: 1300 mm

- Depth: 1200 mm

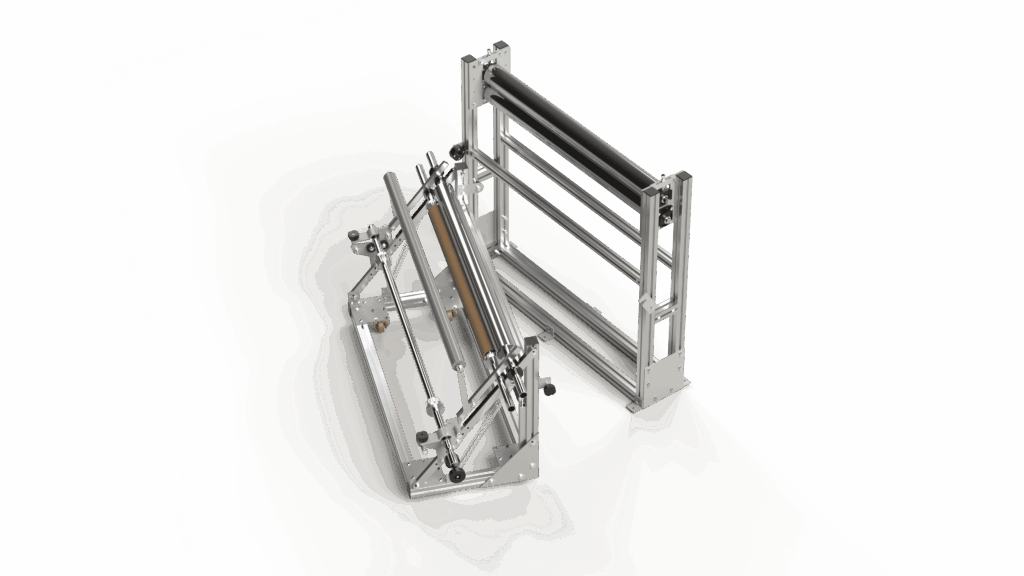

Fellt Applicator ARU - Prevent Capillarity - Automatic Operation with Profiling Line

Overview

The applicator enables the application of anti-condensation fleece to the sheet metal from below with an empty space without fleece application.

The space without fleece can be programmatically adjusted from 6 cm to 30 cm or more, as desired. The profiling line must be stopped twice. Once for cutting and gluing the fleece to the sheet metal and once for cutting the sheet metal to the predetermined panel length.

A software change is required on the profiling line, which must be performed by the manufacturer of the profiling line or a qualified electronics technician who is familiar with the software on the profiling line.

Key Features and Advantages

- Fixed frame with pressure rollers

- Movable applicator frame, which can be pulled out to the left or right of the profiling line for easier replacement and insertion of the anti-condensation fleece roll

- If there is no space to the left and right of the profiling line, a fixed version is possible

- Film winding with a servo motor with film winding tension adjustment

- Automatic pneumatic brake that changes the film tension according to the diameter and weight of the anti-condensation fleece roll

- Automatic adjustment of the fleece running according to the sheet metal with sensors and a transverse electric motor

- Cylinders for pressing and gluing the fleece to the sheet metal

- Sensor for indicating and warning of empty fleece rolls

- Pneumatic pressure rollers with regulation of fleece pressure on the sheet metal

- Hot wire fleece cutting is adjusted on the control panel

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Top-tier automated system for high-volume manufacturing lines. Servo-driven controls. Pneumatic pressing rollers. Fully programmable electrical control box with automatic roll change and hot-wire cutting.

- Servo-driven control; modular frame; pneumatic pressing; automatic roll change; hot-wire cutting.

Dimensions

- Width: 2100 mm

- Height: 1800 mm

- Depth: 2200 mm

Felt Applicator ARU - UNWINDING – WINDING FELT DEVICE

Overview

The winding and unwinding device enables the winding of rolls of film or other materials to smaller diameters and lengths.

Key Features and Advantages

- Modular ALU BOSCH frame for flexible machine configuration

- Supports unwinding rolls with a maximum diameter of 1000 mm or more for increased production capacity

- Winding roll maximum diameter up to 500 mm for efficient coil handling

- Equipped with an electric gearbox motor allowing adjustable winding speeds to match production needs

- Incorporates an automatic or manual winding meter counter for precise length control

- Includes a brake on the unwinding roll for tension adjustment to ensure uniform winding quality

- Features a quick-release pneumatic clamping shaft for fast and easy set roll replacement

Technical Specifications

- Roll diameter: up to Ø1000 mm

- Drive option: manual or EM 24 V motor with servo control

- Frame: modular ALU BOSCH construction

- Movement: mobile on heavy‑duty wheels, lockable

- Pressing rollers: adjustable height with pneumatic assist

- Anchoring: 6‑point ground fixing system

- Top-tier automated system for high-volume manufacturing lines. Servo-driven controls. Pneumatic pressing rollers. Fully programmable electrical control box with automatic roll change and hot-wire cutting.

- Servo-driven control; modular frame; pneumatic pressing; automatic roll change; hot-wire cutting.

Dimensions

- Width: 2100 mm

- Height: 1800 mm

- Depth: 2200 mm

Contact Us

For all technical or commercial inquiries, please feel free to use the contact form below to get in touch with us.